INDUSTRY: Minging, Aggregates • material type: Hard Rock

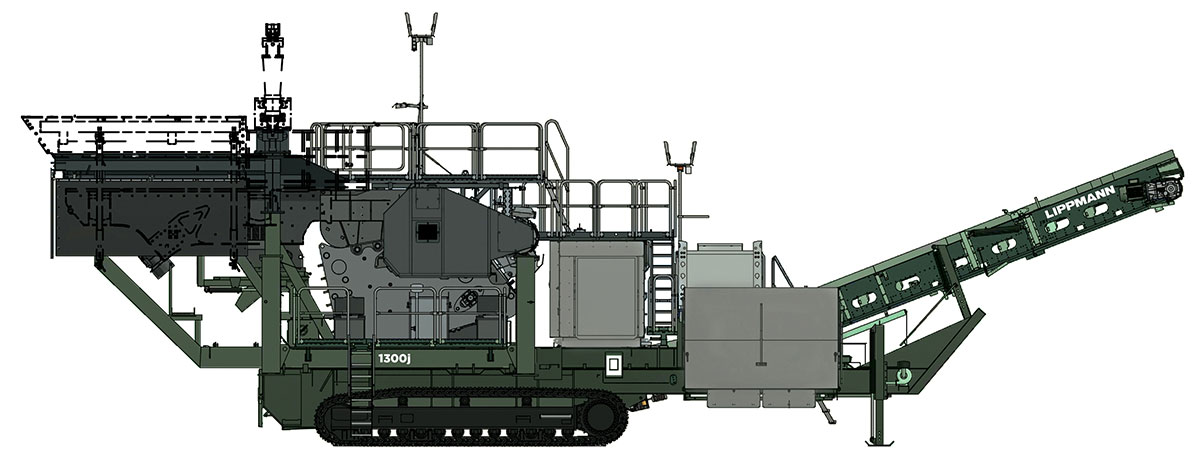

TRACKED JAW CRUSHER

1300j-te

Utilizing smart design with high operational reliability, the 1300j conveniently switches from generator to electric mains so you can always select the most economical power source. When alternating between diesel and electric, you’ll always enjoy stable, efficient production with little environmental impact.

An impressive 51″ x 39″ crushing jaw features a large intake that accepts some of the largest of mining and aggregate material in the industry. A central dashboard is designed for easy monitoring of your most relevant machine data.

Transport weight is kept as minimal as possible thanks to the plant’s ability to separate into two parts—also a key benefit for accessibility when service or maintenance is required

Highlights

2-Step grizzly feeder with

rubber-lined pan

Optional boom & hammer

Hybrid design powered by onboard

diesel generator or connection to

line power

Adjustable main conveyor with 12' 0" - 14' 7"

(3600 - 4450mm) discharge height with 55"

(1397mm) belt width

Self-regulating front jack legs

Split structure for 2-piece transportation

3951j Jaw Crusher with hydraulic

Closed-Side Setting (CSS) control

Radio remote controlled tracks

16' 0" (4.9m) side wall extensions

The Lippmann Edge

Hybrid power solution offers flexibility and makes it possible to always select the most economical power source.

The 1300j’s 3951j jaw structure is pinned and bolted with no welded parts. Features a CSS of 4″ – 11″ (100- 280mm) and hydraulic adjustment.

Standard telematic control system delivers machine data to a central dashboard for convenient monitoring of belt scales, automation system, generator/engine, and alarm logs and diagnostics.

Standard Features & Options

Standard Features

- 51″ x 39″ Jaw opening

- Hydraulic closed side setting adjustment

- JF 1250 feeder with 2-step grizzly

- Hopper and chutes lined with wear plates

- Telematics control system with 10″ (254mm) screen

- Adjustable conveyor under the crushing chamber

- Emergency stops on strategic locations on the unit

- Ladders, stairs, platforms with rails at necessary places

- Jobsite lights with 230V LED, and 24V LED spotlight

- Ground-level diesel tank access for Genset

- Electric control cabinet with PLC monitoring and PC

- Self-regulating front jack legs

- Radio-controlled tracks

Options

- Longer 20′ 0″ (6000mm) feeder avaliable

- Advanced telematics

- Electronics prepared for main supply

- Belt scale

- Ultrasonic cavity level sensor

- Magnetic seperator

- Water spraying

- Air compressor

Benefits of Electric

- Increased reliability: dual-powered plant can run off diesel until site is more established for electric

- Economically beneficial: easily switch from 400 kVA generator to electric mains operation

- Environmentally sound: produce material with little possibility of environmental impact

- Hybrid flexibility: the choice to select the most economical power source is always in your hands

Standard Safety Features

- Engine safety shutdown systems

- Full safety guarding on all nip points

- Tagout capability on isolator

- External belt alignment points

- External grease points

- Startup siren with 10-second delay

- Emergency stops: 4 off, 2 feeder, 2 power unit

Technical Specs

| CRUSHING CHAMBER | ||

|---|---|---|

| 3951j Jaw | US | METRIC |

| Feed opening – WXD | 51″ x 39″ | 1300 x 1000mm |

| CSS | 4′ 11″ | 100 – 280mm |

| Operating speed | 220 rpm | 3.67 Hz |

| Crusher stroke | 1-5/8″ | 41mm |

| Feed size | 32″ | 800mm |

| Tons Per Hour | 300-915 STPH | 270-830MTPH |

| CLOSED SIDE SETTING (CSS) | |||||||

|---|---|---|---|---|---|---|---|

| inches | 2.75 | 3.125 | 3.5 | 4 | 5 | 6 | 7 |

| mm | 70 | 79 | 89 | 102 | 127 | 152 | 178 |

| STPH | 195-295 | 215-295 | 235-330 | 260-360 | 315-435 | 375-515 | 430-595 |

| MTPH | 177-240 | 195-268 | 213-299 | 236-327 | 286-395 | 340-467 | 390-540 |

| POWERUNIT AND ELECTRICS/HYDRAULICS | ||

|---|---|---|

| US | METRIC | |

| Engine option 1 | CAT C9.3B Tier 4F/Stage 5, 416 Hp | CAT C9.3B Tier 4F/Stage 5, 310kW |

| Engine option 2 | CAT C9.3B Tier 3, 416 Hp | CAT C9.3B Tier 3, 310kW |

| Engine speed | 1500 rpm – 50Hz, 1800 rpm – 60Hz | 1500 rpm – 50Hz, 1800 rpm – 60Hz |

| Generator | WEG GTA31 420Kva | WEG GTA31 420Kva |

| Hydraulic powerpack pump | Rexroth A10VO100 | Rexroth A10VO100 |

| Hydraulic powerpack motor | WEG 74 hp 4 pole, operates up to 121 hp maximum | WEG 55kW 4 pole, operates up to 90kW maximum |

| Flowrate maximum | 40 GPM – 50Hz, 48 GPM – 60Hz | 150 LPM – 50Hz, 180 LPM – 60Hz |

| Hydraulic tank capacity | 79.25 gal | 300L |

| DISCHARGE CONVEYOR | ||

|---|---|---|

| US | METRIC | |

| Length | 59′ | 18.00m |

| Width | 55′ | 14.00m |

| Height | 12’0″ – 14′ 7″ | 3.60m – 4.45m |

| Operating Speed | 4.2 ft/s | 1.3m/s |

| FEEDER | ||

|---|---|---|

| US | METRIC | |

| Type | JF 1250 with grizzly | JF 1250 with grizzly |

| Dimensions | 16′ 5″ x 3′ 10″ | 5000mm x 1200mm |

| TRANSPORTATION | ||

|---|---|---|

| US | METRIC | |

| Length | 58′ 10.6″ | 17.96m |

| Width | 10′ 2″ | 3.10m |

| Height | 12′ 9.5″ | 3.90m |

| Weight (Estimated)* | 164.240 lbs | 74,500kg |