INDUSTRY: Aggregates • material type: Hard Rock

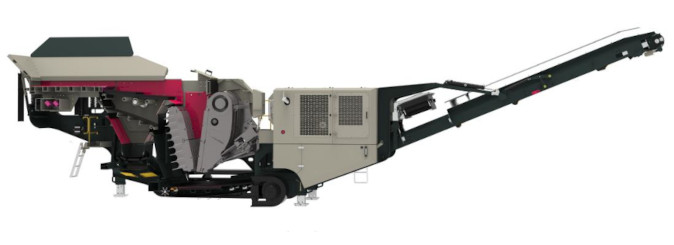

TRACKED JAW CRUSHER

1060j-t

Crushing operations looking for mobility and crushing Capacities in excess of 400 TPH in one product turn to the Lippmann 1060j-t, one of the most powerful in the jaw crusher product range. The 1060j-t is designed to maximize output of high quality material, with a heavy duty build and high quality wear parts and components to minimize downtime.

Highlights

48” (1200mm) belt with hydraulic adjustable angle for large stockpile capacity

Power system includes choice of Tier 3 or Tier 4F/Stage 5 engine for genset

DSE control panel

with line connections

(on other side of machine)

High inertia single toggle 42” x 28” (1060 x 700mm) jaw with heavy-duty bolted construction

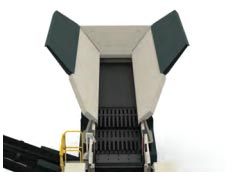

Hydraulic fold and wedge lock hopper, optional extensions

Open chassis design for ease of maintenance

Hydraulic jacking legs

Heavy duty bolt-on tracks with smooth start/stop 3-speed system

The Lippmann Edge

Optimized Material Flow

Lippmann engineers optimized material flow and the jaw chamber design for high productivity and maximum throughput.

Deep Jaw Chamber

Our deep jaw chamber with single toggle design accommodates hard rock applications and large feed sizes. Also features closed side setting adjustment with hydraulic wedges.

Double deck pre-screen

Double deck grizzly pre-screen featuring hydraulic fold and wedge lock hopper, and optional cassettes – punch plate or fingers.

Large Gap Below Crushing Chamber

The large gap between crusher discharge and main conveyor belt, paired with wide main and side conveyors result in an optimized material flow.

Electric Power (Exclusive to "e" models)

Electric operation on select jaw plant models is the latest in a long line of Lippmann innovation since 1923. Designed with the customer in mind, these electric jaw crushers cost less to run while taking reliability to new levels.

Standard Features & Options

Standard Features

- 1060mm wide x 700mm single toggle jaw

- Choice of CAT or Volvo, LRC or T4F/Stage V engines

- HD crawler tracks

- Fast setup time

- Integrated hydraulic folding hopper

- Integrated hydraulic folding stockpiling conveyors

- I-beam plate fabricated chassis construction

- Quick release jaw for transport

- Large gap between crusher discharge and main conveyor feedboot

- Open chassis design for ease of maintenance

Technical Specs

| SPECIFICATIONS | ||

|---|---|---|

| Feed Opening | 42” (1060mm) | |

| Crusher Drive | Hydraulic – V-Belt | |

| Min. Opening | 2.8” (70mm) | |

| Max. Opening | 8” (200mm) | |

| CSS Adjustment | Hydraulic Wedges | |

| Level Sensor | Ultrasonic | |

| HOPPER | ||

|---|---|---|

| Hopper Length | 13’ 8.3” (4175mm) | |

| Hopper Width | 8’ (2342mm) | |

| Hopper Volume | 7.6 yd3 (5.8m3) | |

| FEEDER | ||

|---|---|---|

| Feeder Width | 41.9” (1064mm) | |

| Adjustable Speed | YES – Via Electrical Proportional | |

| Drive | Hydraulic | |

| CONVEYOR | ||

|---|---|---|

| Stockpile Height | 12’ 10” (3912mm) | |

| Belt Width | 48” (1200mm) | |

| Angle Adjustable | YES | |

| Quick Release | YES | |

| ENGINE | ||

|---|---|---|

| Engine Option 1 | Volvo D11 T4F/Stage V, 360 hp (270kW) | |

| Engine Option 2 | CAT C9.3B T4F/Stage V, 416 hp (310kW) | |

| Engine Option 3 | CAT C9.3 LRC, 416 hp (310kW) | |

| Engine Speed | 1800 rpm | |

| Fuel Tank Capacity | 141 US gal (535L) | |

| Hydraulic Tank Capacity | 272 US gal (1030L) | |

| DIMENSIONS | ||

|---|---|---|

| Transport Length | 53’ 2” (16.20m) | |

| Transport Width | 9’ 6” (2.90m) | |

| Transport Height | 11’ 5.8” (3.50m) | |

| Operating Length | 50’ 8” (15.44m) | |

| TOTAL WEIGHT | ||

|---|---|---|

| Total Weight | 106,900 lbs (48,500kg) | |