INDUSTRY: Aggregate, Recycle

material type: Rock, Concrete

Secondary Wheeled Impact CRUSHER

5165is-w

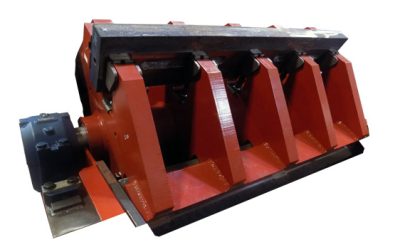

The 5165is-w is a secondary impact crushing plant perfectly suited to be paired up with a primary jaw crusher. The screen plant and impactor are perfectly paired to size the material for your required specification.

The impactor is heavy-duty enough to handle recycle material and will withstand the tramp metal that might be present from the primary crusher. The top cross conveyor is extended to ensure you can take both products out on the same side of the plant.

Highlights

One gravity and one spring-loaded

curtain, optional third grinding curtain

Elevated operator's platform with

ladder access from main platform

51" x 65" horizontal shaft with

40" x 66" feed inlet opening

Four replaceable blow bars, each with

four wear positions for maximum utilization

Two stacked cross conveyors for discharge on the same side

of the plant, and one rear discharge fines conveyor

Optional NEMA - 12 motor control

center with dust tight enclosure (not pictured)

6’ x 20’ three shaft, three deck horizontal screen

I-beam welded steel truck frame with structural cross members

The Lippmann Edge

Long Life Hammers

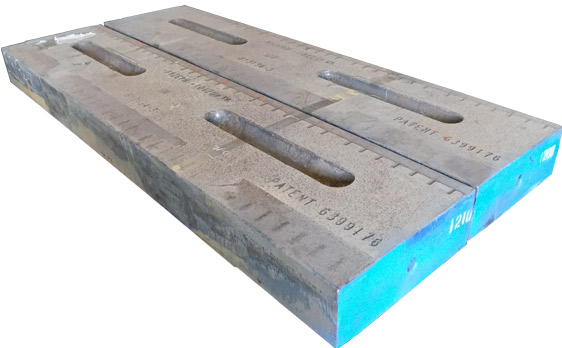

Hammers are rectangular in shape with four wear positions. This shape provides the most even production and product gradation. When utilized correctly, each blow bar will offer four flips, extending the life of the wear components. Depending on the application, Lippmann can provide a variety of different hammer compositions. From high chrome, high carbon limestone applications to low chrome, low carbon recycle applications, Lippmann is able to provide the correct blow bar for the job.

Premium Shaft and Rotor

The premium, high alloy steel shaft is held with keyless locking assemblies. These keyless locking rings offer superior locking capabilities over keyed shaft applications due to the impact bending loads that are experienced. The rotor houses premium blow bars using a jack and stand configuration. The force of the jacking assembly causes the hammers and rotor backing beams to act as a solid mass while crushing. This rigid, machine fit enables the use of more wear resistant, higher chrome hammers and yields greater production before turning or replacing hammers.

Easily Adjustable Curtains and Wear Resistant Liners

To ensure efficiency, all frame and apron liners are drilled and tapped using a standard hex head cap screws and locking washers. Liners are a premium, abrasion-resistant materials that are easily replaceable after wear. Curtain position is maintained through a combination of both gravity and spring loaded configurations, allowing for easy adjustment from outside of the crusher.

Technical Specs

| GENERAL SPECIFICATIONS | ||

|---|---|---|

| Impactor | 51″ x 65′ | |

| RPM | 425-577 rpm | |

| Pan Feed Size | 48″ x 72′ | |

| Operating Speed | 1150 rpm | |

| Folding Top Cross Conveyor | 24″ x 16′-6″ | |

| Operating Speed | 300 fpm | |

| Bottom Cross Conveyor | 24″ x 10″-1″ | |

| Operating Speed | 745 rpm | |

| Under screen Conveyor | 60″ x 30′ | |

| Operating Speed | 292 fpm | |

| Screen Size | 6′ x 20″ | |

| Operating Speed | 745 rpm | |

| Decks | 3 | |

| HORSEPOWER | ||

|---|---|---|

| Impactor | 300 | |

| Screen | 40 | |

| Pan Feeder | x2 2.5 | |

| Top Cross Conveyor | 5.5 | |

| Bottom Cross Conveyor | 5.5 | |

| Under Screen Conveyor | 15 | |

| WEIGHTS | ||

|---|---|---|

| WITH SCREEN | WITHOUT SCREEN | |

| Quad | 84,500 lbs | 65,500 lbs |

| King Pin | 46,250 lbs | 44,000 lbs |

| Total | 130,750 lbs | 109,500 lbs |

Lippmann reserves the right to make changes to the information and design of the machines on this website without reservation and notification to the users. Information at time of publication is considered accurate – Lippmann assumes no liability resulting from errors or omissions in this document.

Standard Features & Options

Standard Features

- Andreas type impact crusher design

- Inspection door on side of the machine

- High ratio of reduction

- Hammers have four crushing positions to maintain a more consistent gradation and greater top size control

- No weld build-up required

- One gravity and one spring-loaded curtain with optional third grinding curtain

Options

- Hydraulic leveling jacks – (4) 70,000 lbs

- Six (6) run-on jack legs

- NEMA 12-motor control center

Diagrams