INDUSTRY: Aggregates, Mining, Recycling

Primary Jaw Crusher

5062j

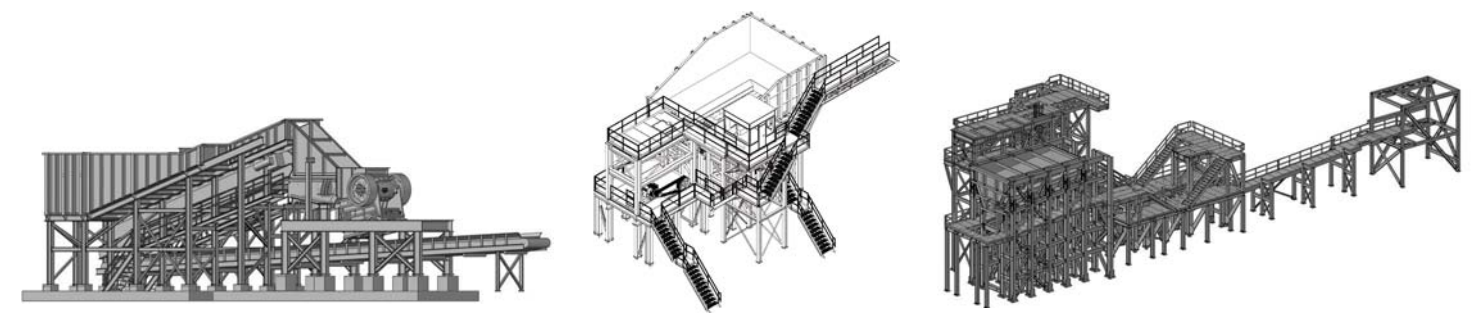

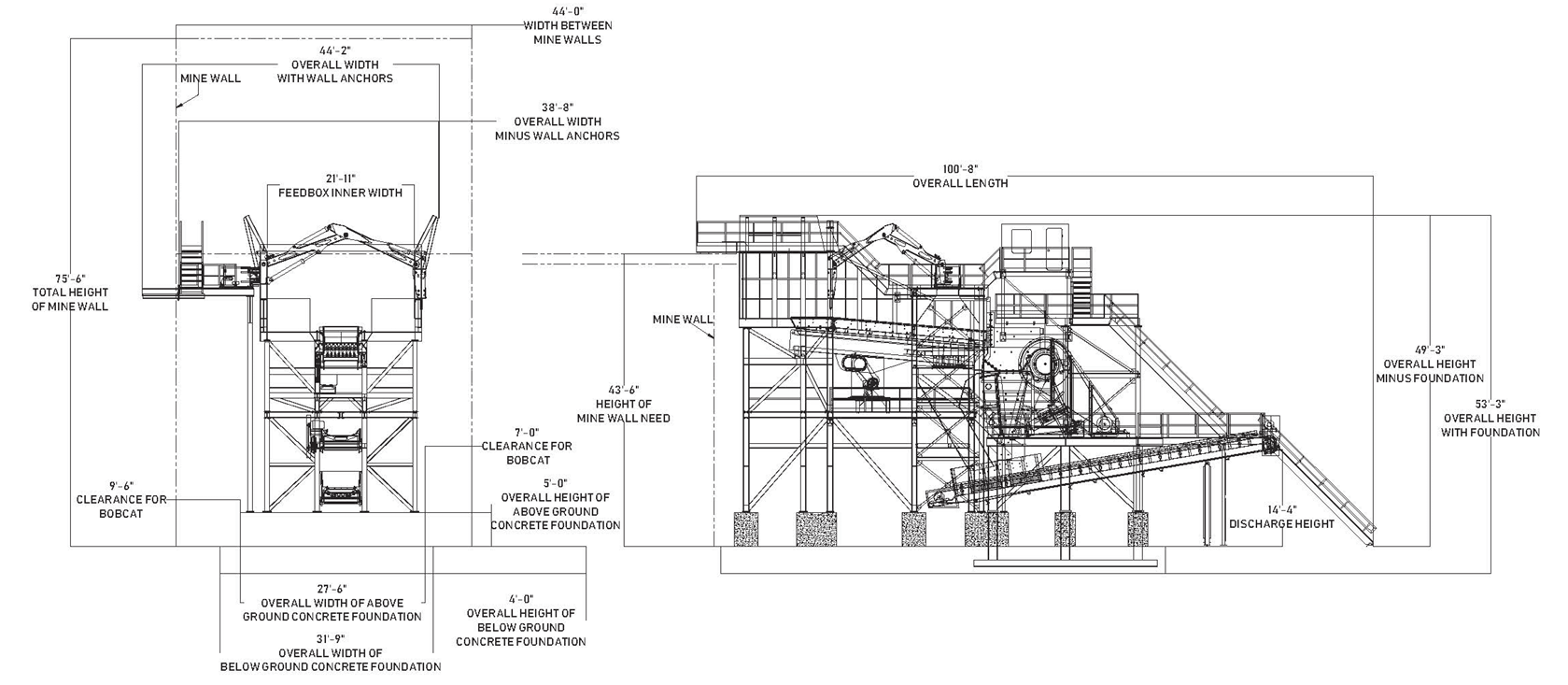

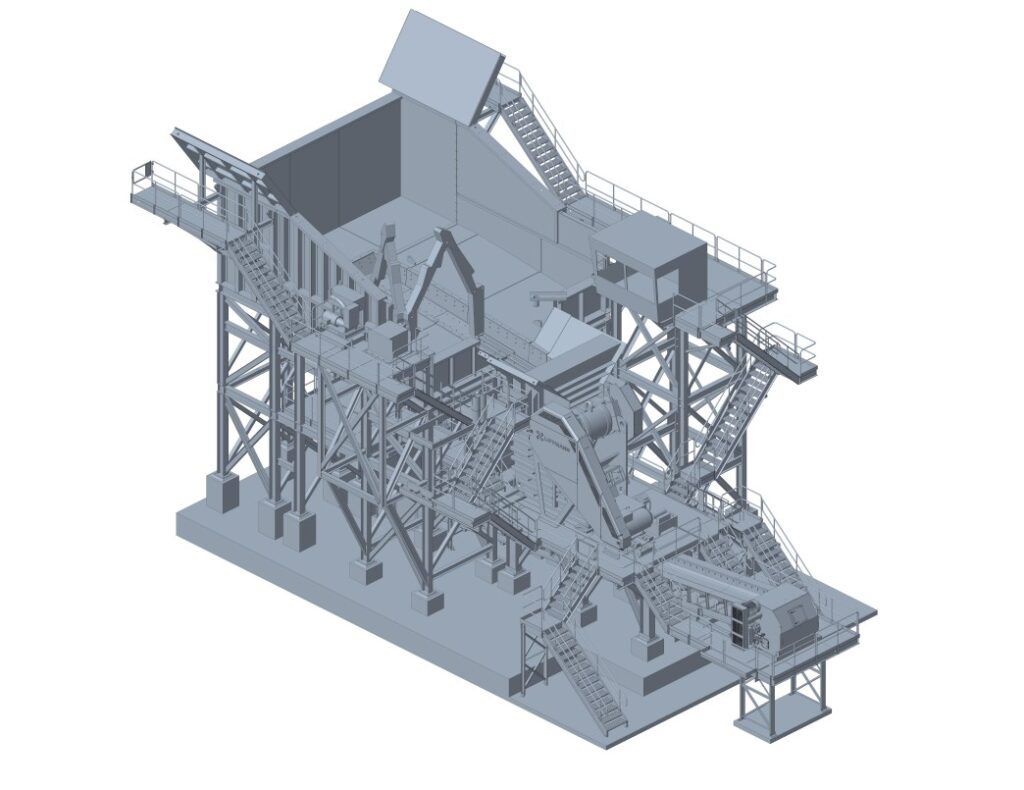

This primary crushing station is designed for heavy-duty and high production applications. With it handling 100-ton trucks this plant is capable of 1800-2200tph.

Lippmann designs custom primary stations that will fit customer needs and demands. Keeping safety in mind, Lippmann has designed these plants with plenty of clearance to easily maintain this large equipment and provide optimum uptime for the customer by allowing material to flow freely.

Highlights

10' Step Grizzly

60"x 50' Discharge Conveyor

Oversized tapered roller bearings in both the pitman and frame. Tapered roller bearings exhibit a greater load carrying capacity compared to an equal sized spherical roller.

An extra heavily ribbed steel frame- stress relieved after welding and before machining.

50" x 62" Jaw with one piece steel pitman and reversible manganese steel jaw dies.

Two heavy-duty flywheels, one grooved for V-belts

Massive rock box with optional extensions handles large front-end loaders.

Operator control office positioned to keep a close eye on productivity.

Standard Features & Options

Standard Features

- An extra heavily ribbed steel frame- stress relieved after welding and before machining.

- Oversized tapered roller bearings in both the pitman and frame.

- Tapered roller bearings exhibit a greater load carrying capacity compared to an equal sized spherical roller used in competitor’s machines

- One piece steel pitman

- Heat-treated forged alloy steel eccentric shaft

- Manganese steel cheek plates

- Reversible manganese steel jaw dies

- Hydraulic toggle adjustment

- Two heavy-duty flywheels, one grooved for V-belts

- Replaceable swing jaw barrel protector

- Replaceable wear plate behind the swing jaw die & stationary jaw die

- Replaceable toe protectors for swing & stationary sides

Options

- Toggle Power Unit

- Taper Wedge

- Manual Toggle Plate

Technical Specs

| SPECIFICATIONS | |

|---|---|

| Jaw Crusher | 50″ x 62″ |

| RPM | 190 rpm |

| Stroke | 3/4″ |

| Feed Size | 45″ |

| Discharge Conveyor | 60″ x 50′ |

| Discharge Conveyor Operating Speed | 320 rpm |

| Feeder | 62″ x 28′ |

| Feeder Operating Speed – Max | 840 rpm |

| Grizzly Length | 10′ |

| CLOSED SIDE SETTING (CSS) | |

|---|---|

| INCHES | STPH |

| 5 | 600-650 |

| 6 | 700-775 |

| 7 | 950-915 |

| 8 | 980-1088 |

| 10* | 1199-1301 |

| 12* | 1400-1499 |

| 14* | 1599-1700 |

*Manual toggle plate option only

Hydraulic toggle or manual toggle plate available

| HORSEPOWER | |

|---|---|

| Jaw Crusher | 300/350 |

| Autolube | 1 |

| Toggle Power Unit (optional) | 7 |

| Taper Wedge (optional) | 1 |

| Feeder | 100 |

| Discharge Conveyor | 50 |

| WEIGHTS (LBS.) | |

|---|---|

| Rock Box Structure | 172,192 |

| Rock Box Assembly | 208,022 |

| Jaw Structure | 308,817 |

| Control House Structure | 41,415 |

| Hammer Structure | 59,593 |

| TOTAL WEIGHT | 790,039 |

Lippmann reserves the right to make changes to the information and design of the machines on this website without reservation and notification to the users. Information at time of publication is considered accurate – Lippmann assumes no liability resulting from errors or omissions in this document.