INDUSTRY: Mining, Aggregates, Recycle

material type: Hard Rock, Concrete, Asphalt

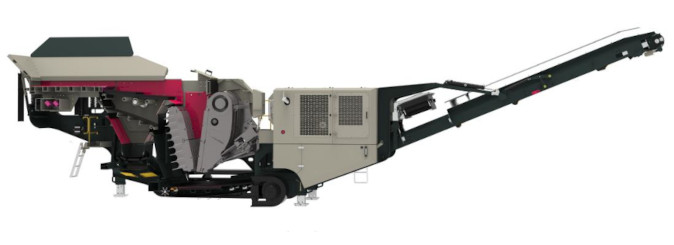

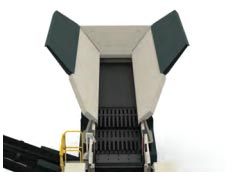

TRACKED JAW CRUSHER

1200j-t

Get a true edge on the job site with the 1200j-t heavy duty track-mounted jaw crusher. With a 75″ (1905mm) deep jaw chamber, this go-to crusher tackles the toughest applications in mining, aggregate, and recycling.

Rely on the 1200j-t for smooth operation and maximum throughput as Lippmann engineers have optimized the material flow and jaw chamber design for high productivity.

Highlights

Hydraulic fold and

wedge lock hopper,

optional extensions

High inertia single toggle

48" x 34" (1200 x 864mm)

jaw with heavy-duty

bolted construction

Open chassis design

for ease of maintenance

Heavy duty bolt-on tracks with

smooth start/stop 3-speed system

Power system includes choice of Tier 3

or Tier 4F/ Stage 5 engine for genset

55" (1397mm) belt with hydraulic adjustable

angle for large stockpile capacity

DSE control panel with line

connections (on other side of machine)

The Lippmann Edge

Optimized Material Flow

Deep Jaw Chamber

Double deck pre-screen

Large Gap Below Crushing Chamber

Electric Power (Exclusive to "e" models)

Standard Features & Options

Standard Features

- Optimized material flow with high TPH

- Large gap between crusher discharge and main conveyor belt

- Wide main and side conveyors

- 48″ x 34″ jaw opening

- Single toggle jaw accommodates large feed sizes

- Closed side setting adjustment with hydraulic wedges

- Electric power

- Line power connection standard

- Connect to line power or onboard generator

- Simplified troubleshooting

- High performance standard features

- 12″ DSE control panel

- High volume fuel tank

- Heavy duty bolt-on tracks

Options

- Quarry jaw die (square profile)

- Super teeth jaw die (wave profile)

- Deflector plate under jaw

- Rock hammer

- 2″ aperture Bofor

- Overband magnet with hydraulic raise and lower

- Rubber base liners in pan feeder

- Rubber hopper side liners

- Hopper extensions

- Refueling pump

- Work lights

- Water pump and dust suppression system

Technical Specs

| CRUSHING CHAMBER | ||

|---|---|---|

| US | METRIC | |

| Feed opening – WXD | 48″ x 34″ | 1200 x 964mm |

| Crusher speed | 230 rpm | 3.83 Hz |

| Crusher stroke | 1.46″ | 37mm |

| Crusher drive | Hydraulic V-belts | Hydraulic V-belts |

| Minimum opening | 2.8″ | 70mm |

| Maximum opening | 8.3″ | 212mm |

| Maximum feed size | 27.5″ | 700mm |

| Crusher weight – bare | 61,730 lbs | 28,000kg |

| CSS adjustment | Hydraulic wedges | Hydraulic wedges |

| Motor | WEG 220hp 6 Pole | 160kW |

| Starter – includes unblock software | WEG VSD | WEG VSD |

| CLOSED SIDE SETTING (CSS) | |||||||

|---|---|---|---|---|---|---|---|

| inches | 2.75 | 3.125 | 3.5 | 4 | 5 | 6 | 7 |

| mm | 70 | 79 | 89 | 102 | 127 | 152 | 178 |

| STPH | 195-295 | 215-295 | 235-330 | 260-360 | 315-435 | 375-515 | 430-595 |

| MTPH | 177-240 | 195-268 | 213-299 | 236-327 | 286-395 | 340-467 | 390-540 |

| POWERUNIT AND ELECTRICS/HYDRAULICS | ||

|---|---|---|

| US | METRIC | |

| Engine option 1 | CAT C9.3B Tier 4F/Stage 5, 416 Hp | CAT C9.3B Tier 4F/Stage 5, 310kW |

| Engine option 2 | CAT C9.3B Tier 3, 416 Hp | CAT C9.3B Tier 3, 310kW |

| Engine speed | 1500 rpm – 50Hz, 1800 rpm – 60Hz | 1500 rpm – 50Hz, 1800 rpm – 60Hz |

| Generator | WEG GTA31 420Kva | WEG GTA31 420Kva |

| Hydraulic powerpack pump | Rexroth A10VO100 | Rexroth A10VO100 |

| Hydraulic powerpack motor | WEG 74 hp 4 pole, operates up to 121 hp maximum | WEG 55kW 4 pole, operates up to 90kW maximum |

| Flowrate maximum | 40 GPM – 50Hz, 48 GPM – 60Hz | 150 LPM – 50Hz, 180 LPM – 60Hz |

| Hydraulic tank capacity | 79.25 gal | 300L |

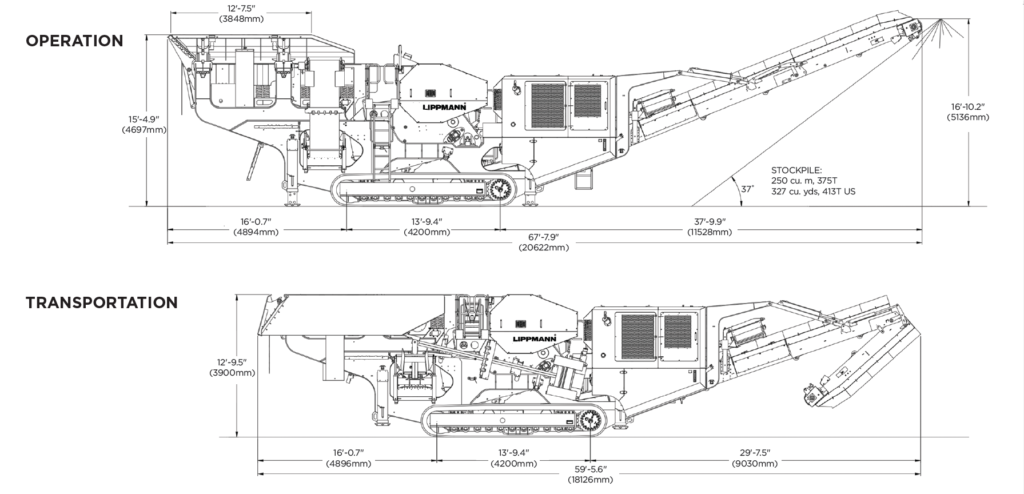

| TRANSPORTATION | ||

|---|---|---|

| US | METRIC | |

| Length | 58′ 10.6″ | 17.96m |

| Width | 10′ 2″ | 3.10m |

| Height | 12′ 9.5″ | 3.90m |

| Weight (Estimated)* | 164.240 lbs | 74,500kg |