Why Primary Crusher Wear Parts Matter for the Whole Circuit?

Keeping a crushing circuit running at full potential isn’t simply adding more power or more machines. It starts with the primary crushers – and specifically, with the jaw crusher wear parts that set your product size, shape, and overall reduction ratio for everything that follows.

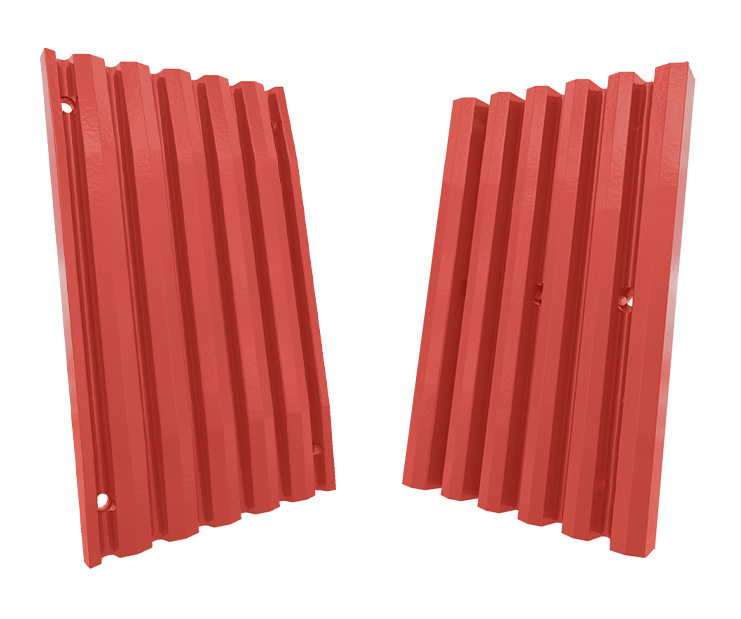

Lippmann heavy-duty jaw plates are engineered to do more than just crush the material. They’re designed as OEM wear parts to the same specifications and standards as Lippmann jaw crushers, delivering safer operation, improved product quality, and lower long-term cost per ton.

No matter what type of crusher you run downstream – cone crushers, gyratory crushers, roll crushers, or impact crushers – they can only perform as well as the feed they receive.

- The size of the material leaving the jaw directly affects your achievable reduction ratio in secondary and tertiary stages.

- Uniform product size from the primary reduces recirculating loads, protects liners, and keeps efficiency reduced to a minimum.

- Better controlled discharge also supports a more stable crushing action in every machine that follows.

That’s why OEM heavy-duty jaw profiles are such a powerful lever for better overall circuit performance, not just jaw crusher uptime.

Heavy Duty Jaw Profiles for Better Material Flow & Wear Life

Traditional jaw plates can struggle with challenging feed material, especially when there’s a lot of fines, slabby rock, or very abrasive material. This is where Lippmann’s heavy-duty jaw profile is different.

Ideal for Challenging Feed and Unscalped Material

In real-life applications, scalping is not always perfect – and sometimes there’s no scalper at all. Heavy-duty jaw profiles are highly effective when:

- There is no scalper, or the scalping process is not efficient.

- The feed material tends to break into flat, slabby pieces.

- You’re processing difficult types of materials with high fines or high abrasion.

Because the jaw plate design allows fine material to pass quickly through the chamber, packing and bridging are reduced. Features like the uneven tooth pattern actively work to break slabs, so you get:

- Fewer blockages in transfer conveyors.

- Less risk of overloading secondary cone crushers or impact crushers with poor-quality feed.

- More consistent performance across all downstream types of crushers, whether you’re running gyratory crushers, roll crushers, or multi-stage cone circuits.

Built for Long-Term Performance and Customer Satisfaction

These heavy-duty jaw profiles are not a short-term fix. They’re a strategic upgrade for long-term performance:

- Better fines removal and optimized tooth height mean manganese lasts longer and wears more evenly.

- Controlled material size leaves the primary supports a high-quality product all the way to the final stockpile.

Even operation across abrasive materials reduces surprises and keeps the circuit stable.

Operations using these OEM profiles report strong customer feedback around:

- Improved shape and consistency of final aggregates – a clear driver of customer satisfaction.

- Reduced unplanned shutdowns because of blockages and packing.

- Lower overall cost per ton, thanks to better utilization of all crusher types in the plant.

In other words, the right jaw profile helps your entire plant deliver a more predictable, high-quality product every shift.

Ready to Improve Your Crushing Action?

If you’re seeing:

- Slabby material in your discharge

- Frequent packing or pegging in the jaw

- Downstream cone crushers or impact crushers are struggling with poor feed

- Maintenance intervals are getting shorter as efficiency is reduced under tough conditions

…then it may be time to review your jaw profile.

Contact your local Lippmann dealer about upgrading to heavy-duty jaw crusher wear parts. They can assess your feed material, operating conditions, and existing setup to recommend the best profile for your application – and help you get more out of your primary crushers and the entire circuit.

Lippmann Primary Jaw Crushers: Fast Facts

Why Lippmann?

- Massive, stress-relieved steel frames

- Long-lasting, reversible jaw dies

- Custom plant designs

- Easy serviceability

Top Models

5062j

Up to 1,700 TPH

50″ x 62″ jaw

Manual toggle plate, taper wedge lock, or hydraulic toggle

4248j

Up to 1,300 TPH

42″ x 48″ jaw

Manual toggle plate, taper wedge lock, or hydraulic toggle

Efficiency & Sustainability

- Fewer replacements = less waste

- Efficient material flow = lower energy use

- Built to be rebuilt, not replaced