INDUSTRY: Mining, Aggregates • material type: Hard Rock

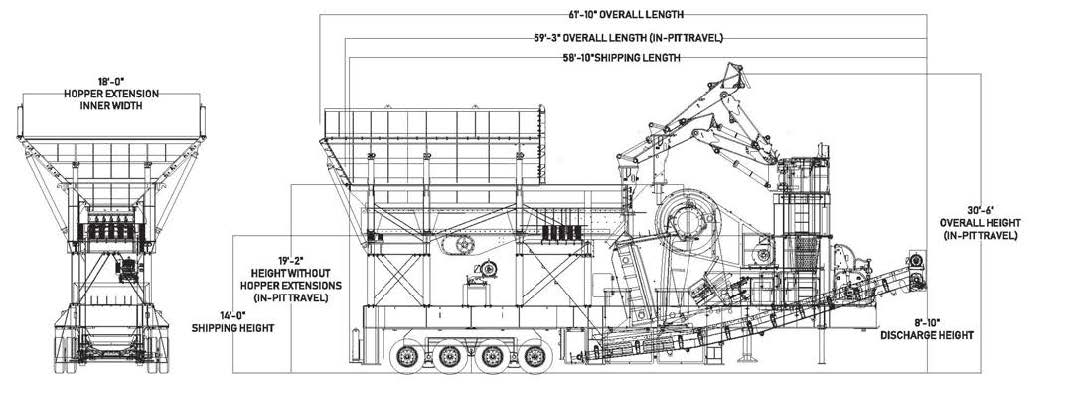

Wheeled Jaw Plant Model

4248j-w

This jaw plant is designed for in-pit crushing, high capacity applications and provides unmatched production and reliability in the market. It features an optional hammer and hopper extensions capable of handling large front end loaders or trucks and is specifically designed to handle 1000+ tons per hour making sure there is enough capacity in the hopper and conveyor to be able to obtain this.

Highlights

Capable of handling large front end loaders or trucks

8-foot step grizzly

Optional: tire bulkheads (not pictured)

An extra heavily ribbed steel frame-stress relieved after welding and before machining

One piece steel pitman

Oversized tapered roller bearings in both the pitman and frame. Tapered roller bearings exhibit a greater load carrying capacity compared to an equal sized spherical roller

Two heavy-duty flywheels, one grooved for V-belts

(4) hydraulic leveling jacks optional

The large rugged size of the hopper and feeder result in them being separate components for install, dismantle and transport.

54-inch wide discharge conveyor

The Lippmann Edge

Oversized Shaft, Dynamically Balanced Flywheels

All Lippmann heavy-duty jaw crushers feature an oversized, heat treated shaft forged of special alloy to provide an exceptionally large eccentric throw. These heavy-duty shafts are paired with two dynamically balanced flywheels, effectively reducing vibration on both portable and stationary crushers. The overhead eccentric configuration does not rely on gravity alone to move material through the chamber. Rather, the inward and downward movement of the swing jaw provides for a forced-feeding motion to maximize output. All shafts are machined and put through a rigorous inspection process before they enter production.

Tapered Roller Bearing for Optimized Bearing Life

Hydraulic Toggle Reduces Setting Time

Reversible Jaw Dies for Longer Life

All standard Lippmann jaw dies (stationary and moving) are reversible. They can be flipped from end to end as necessary to get better lifespan out of them. The corrugated design that is centered about the jaw crusher allows this. Lippmann uses a peak to valley arrangement to break the rocks, using shear rather than direct compression.

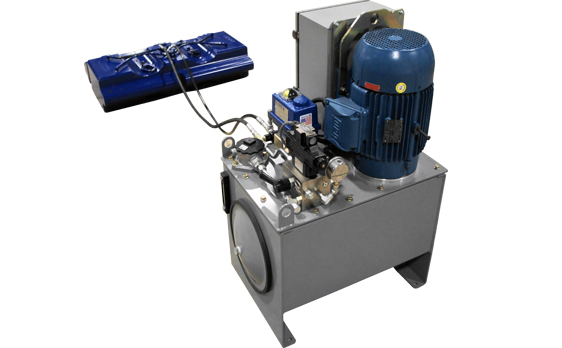

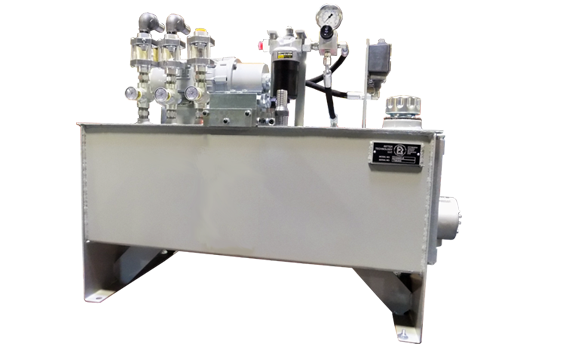

Oil-Bath Lubrication System

Taper Lock

Safety at Every Step

Standard Features & Options

Standard Features

- Extra-heavy ribbed steel frame is stress-relieved after welding and before machining

- One-piece steel pitman

- Heat-treated forged alloy steel eccentric shaft

- Manual toggle adjustment

- Bolt in replaceable toggle bearings

- Oversized tapered roller bearings in both the pitman and frame. Tapered roller bearings exhibit a greater load carrying capacity compared to an equal sized spherical roller

- Reversible manganese steel jaw dies and extensions

- Manganese steel cheek plates

- Swing jaw barrel protector

- Replaceable wear plate behind the swing jaw die & stationary jaw die

- Automatic Oil Lubrication System which delivers a metered flow of filtered oil to each bearing

- Two heavy-duty flywheels, one grooved for V-belts

Options

- 10′ grizzly section

- Hydraulic leveling jacks – (4)

- NEMA 12-motor control center

- Hopper extensions (only non-folding)

- Hydraulic toggle

- Taper lock

- Tire bulkheads

Technical Specs

| 4248j-w SPECIFICATIONS | ||

|---|---|---|

| Jaw Crushers | 42″ x 48″ | |

| RPM | 220 rpm | |

| Feed Size | 38″ | |

| Discharge Conveyor | 54″ | |

| Operating Speed (loaded) | 830 rpm | |

| Feeder | 56″ x 26′ | |

| Feeder Operating Speed – Max | 830 rpm | |

| Grizzly Length | 8′ Step | |

| CLOSED SIDE SETTING (CSS) INCHES | |||

|---|---|---|---|

| INCHES | |||

| 4 | 386-489 | ||

| 4.5 | 441-550 | ||

| 5 | 489-595 | ||

| 12 | *1069-1178 | ||

| 14 | *1179-1309 | ||

*Manual toggle plate option only

See page 2-10 from the Lippmann Jaw Book for values

4248 can be set from 4” to 8” (14” toggle plate only)

| HORSEPOWER | ||

|---|---|---|

| Jaw Crusher | 250 | |

| Autolube | 1 | |

| Toggle Power Unit (optional) | 7 | |

| Taper Wedge (optional) | 1 | |

| Feeder | 75 | |

| Discharge Conveyor | 30 | |

| TRANSPORTATION (LBS) | ||

|---|---|---|

| Tires | 315/80R22.5 | |

| Rear Axle | 66,500 | |

| King Pin | 33,500 | |

| TOTAL | 100,000 | |

| Weight of Feeder Module | 52,000 | |

| Weight of Jaw | 136,000 | |

| Fall Off Load | 54,000 | |

| TOTAL WEIGHT | 342,000 | |

Lippmann reserves the right to make changes to the information and design of the machines on this website without reservation and notification to the users. Information at time of publication is considered accurate – Lippmann assumes no liability resulting from errors or omissions in this document.