INDUSTRY: Mining, Aggregates • material type: Hard Rock

Wheeled Jaw Plant

3447j-w

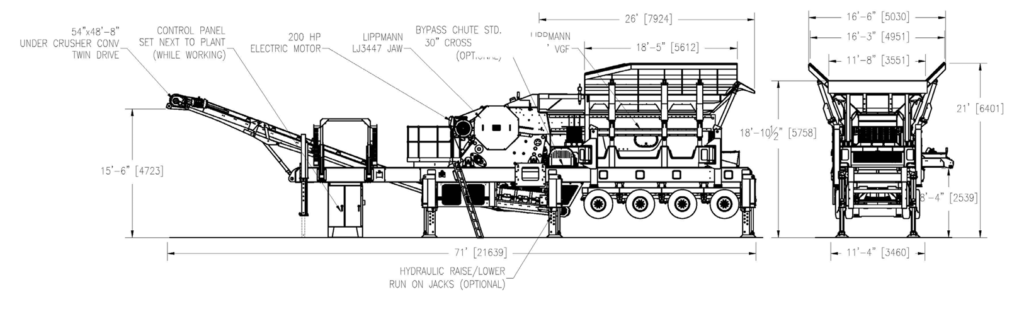

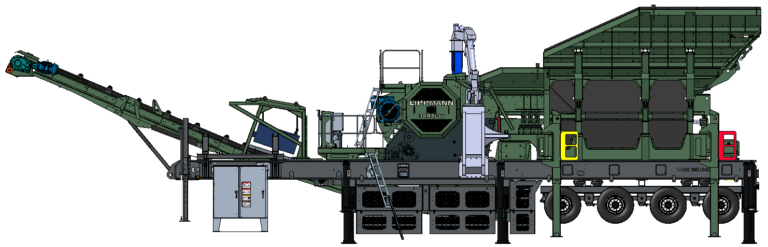

The 3447j-w wheeled jaw plant was developed to be a high tonnage crusher with both the ease of maintenance and transportability. The 34” gape allows you to feed a 27.5” rock with ease. The jaw also features an opposing wedge design that allows the producer to make adjustments easily and safely.

Highlights

48” single toggle jaw with 34” gape allows you to feed a 27.5” rock

Open wheeled chassis for ease of maintenance

Jaw features an opposing wedge design

Large 51” x 20’ pan feeder with 5' grizzly section

54" wide discharge conveyor

The Lippmann Edge

Oversized Shaft, Dynamically Balanced Flywheels

All Lippmann heavy-duty jaw crushers feature an oversized, heat treated shaft forged of special alloy to provide an exceptionally large eccentric throw. These heavy-duty shafts are paired with two dynamically balanced flywheels, effectively reducing vibration on both portable and stationary crushers. The overhead eccentric configuration does not rely on gravity alone to move material through the chamber. Rather, the inward and downward movement of the swing jaw provides for a forced-feeding motion to maximize output. All shafts are machined and put through a rigorous inspection process before they enter production.

Tapered Roller Bearing for Optimized Bearing Life

Hydraulic Toggle Reduces Setting Time

Reversible Jaw Dies for Longer Life

All standard Lippmann jaw dies (stationary and moving) are reversible. They can be flipped from end to end as necessary to get better lifespan out of them. The corrugated design that is centered about the jaw crusher allows this. Lippmann uses a peak to valley arrangement to break the rocks, using shear rather than direct compression.

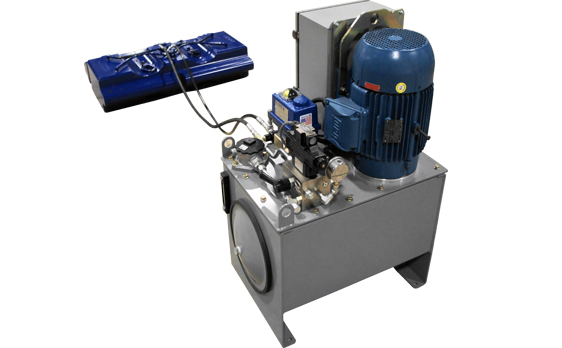

Oil-Bath Lubrication System

Taper Lock

Safety at Every Step

Standard Features & Options

Standard Features

- 48” single toggle jaw c/w 200 HP motor

- Integrated motor mount

- Open wheeled chassis for ease of maintenance

- Heavy duty chassis for semi towing

- Heavy duty 4 axle spring suspension

- Chassis cable hooks

- Fast setup time

Options

- 30” cross conveyor for grizzly bypass

- Three discharge conveyor options:

- 12’-9” discharge, single scraper, impact idlers (only available with self-cleaning permanent magnet)

- 15’-6” folding, single scraper, impact idlers (only available with self-cleaning permanent magnet)

- 16’-3” folding, dual scraper, brunon impact bed (only available with stationary electro-magnet)

- Feeder grizzly options:

- 4-1/2” spacing

- 5-1/2” spacing

- 7” spacing

- Hopper options:

- Manual lift off

- No wings (AR liners)

- 16ft width with wings (AR liners)

- Hydraulic lift off

- No wings (AR liners)

- No wings (rubber liners)

- 20ft width w/wings (rubber liners)

- 16ft width w/wings (AR liners)

- Tipping grid (AR liners)

- Manual lift off

- Optional chassis mounted hammer

- Optional electrical control panel (cable termination box as standard)

- Optional manual or hydraulic lift off panel (if panel option is selected)

Technical Specs

| 3447j-w SPECIFICATIONS | ||

|---|---|---|

| Jaw Crushers | 34″ x 47″ | |

| Feed Size | 27.5″ | |

| Discharge Conveyor | 54″ | |

| Side Conveyor | 30″ | |

| Pan Feeder | 51″ x 20′ | |

| Bypass Chute Std. | Optional | |

| Electric Motor (no diesel drive option) | 200 hp | |

| Grizzly Section | 5′ | |

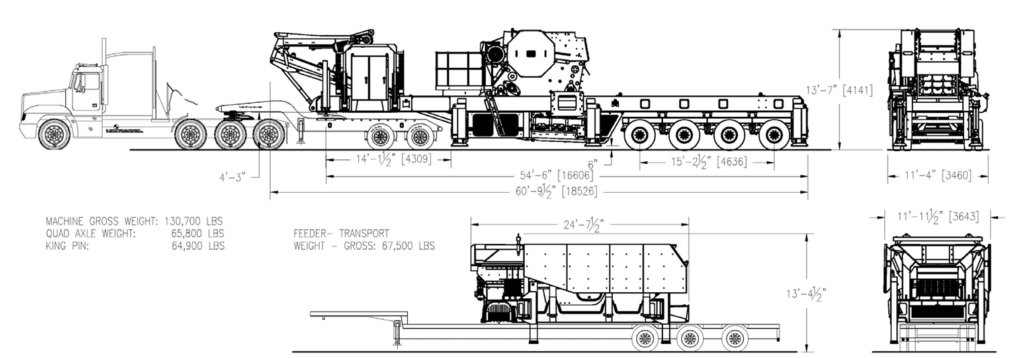

| TRANSPORTATION DIMENSIONS | ||

|---|---|---|

| Length | 60′ – 10″ | |

| Width | 13′ – 7″ | |

| Height | 11′ – 4″ | |

| TRANSPORTATION WEIGHTS (ESTIMATED LBS.) | ||

|---|---|---|

| Plant Gross (conveyor option B) | 130,700 | |

| Quad | 65,800 | |

| King Pin | 64,900 | |

| Hopper (16ft wings with AR liner) | 67,500 | |

Lippmann reserves the right to make changes to the information and design of the machines on this website without reservation and notification to the users. Information at time of publication is considered accurate – Lippmann assumes no liability resulting from errors or omissions in this document.