INDUSTRY: Mining, aggregate, recycle

material type: hard rock, limestone, concrete asphalt

Feeders

Highlights

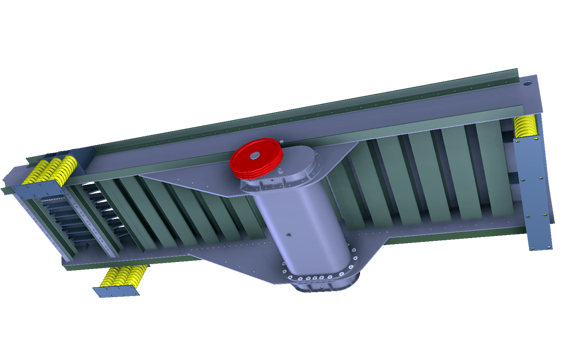

Lippmann feeders are driven by a dual shaft, field-proven eccentric drive mechanism. The specialized flow-through tube arrangement of the vibe housing encases a large oil reservoir that continuously lubricates all moving components while at the same time dispersing heat.

The Lippmann Edge

Strong, Trouble-Free Operation

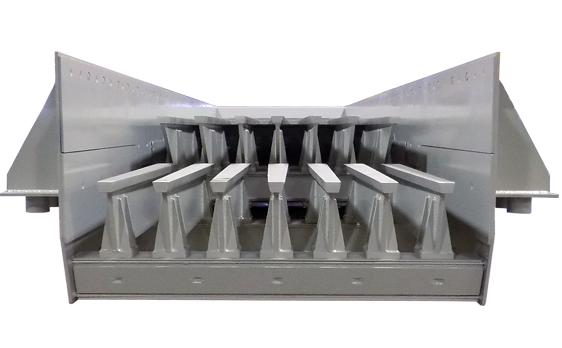

The two overriding advantages of the Lippmann series feeders are the sound design and maximization of strength. To ensure strong, trouble-free operation, Lippmann engineers have designed the vibrating gold rush grizzly feeder for maximum strength at all crucial stress points. Each aggregate feeder features extra heavily reinforced cross members that run the entire course of the unit. Adding to the strength and overall durability, each Lippmann vibrating feeder comes standard with replaceable steel liners on the feeder pan and side plates.

Field-Proven Eccentric Drive Mechanism

Choice of Adjustable Grizzly Configurations

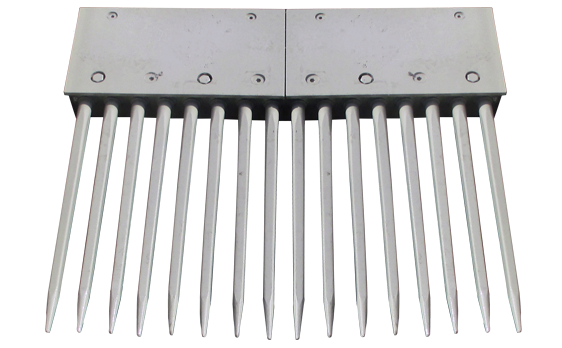

Lippmann Grizzly Finger Cartridges

An additional option on all feeders is replacing grizzly bars with Lippmann grizzly spring fingers. These steel fingers are loaded into the wash feeder as a single, cartridge-like unit. Lippmann fingers have a distinct advantage in some applications due to their ability to “cut” material and remove large quantities of undersized material before entering the crusher.

Low Profile Design

Low profile side plates minimize height which is critical for road-able crushing plants. Heavy coil springs at each side on the discharge end isolate vibrations and stabilize the gold rush feeder for smooth operation.

Standard Features

Feeder Features

- Strong, trouble-free operation

- Heavy-duty feeder I-Beam pan and pan support members guard against the most severe impacts

- Sturdy grizzly bar

- More ductile grizzly finger options

- Varying lengths and adjustable bars and fingers

- Allows maximum fines to bypass and prevents materials from “pegging”

- Available in single or step-deck configurations

- Superior eccentric drive mechanism

- Heavy-duty, field-proven eccentric drive mechanism provides straight- line motion to straighten out slabby material and reduce bridging at the crusher feed opening

- Open, flow-through tube arrangement permits oil to circulate constantly through the large, double-sealed vibrator assembly

Technical Specs

| FEEDER SIZE inch x feet mm x mm | VIBRATOR SIZE | CAPACITY | GRIZZLY SECTION LENGTH 1 feet mm | WEIGHT 2 Lbs. Kg | A | B* | C | D | E | H | L | OS | S* | W | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STPH | MTPH | ||||||||||||||

| 38 x 16 965 x 4877 | LLH-18 | 400-600 | 360-540 | 4, 5 1219, 1524 | 8,800 3,990 | 6 152 | 13′-9″ 4191 | 18 457 | 11 279 | 12 305 | 41 1041 | 17 5182 | 63 1600 | 55 1397 | 38 965 |

| 38 x 20 965 x 6096 | LLH-18 | 400-600 | 360-540 | 4, 5, 6 1219, 1524, 1829 | 11,000 4,980 | 6 152 | 13′-6″ 4115 | 24 610 | 8 203 | 12 305 | 47 1194 | 21 6401 | 63 1600 | 55 1397 | 38 965 |

| 45 x 16 1143 x 4877 | LLH-18 | 500-650 | 450-590 | 4, 5 1219, 1524 | 10,500 4,760 | 6 152 | 13′-9″ 4191 | 24 610 | 8 203 | 12 305 | 47 1194 | 17 5182 | 62 1575 | 70 1778 | 47 1194 |

| 45 x 20 1143 x 6096 | LLH-18 | 500-650 | 450-590 | 4, 5, 6 1219, 1524, 1829 | 12,000 5,440 | 6 152 | 16′-6″ 5029 | 24 610 | 8 203 | 12 305 | 47 1194 | 21 6401 | 62 1575 | 70 1778 | 47 1194 |

| 47 x 16 1194 x 4877 | LLH-18 | 550-700 | 500-640 | 4 1219 | 11,000 4,980 | 6 152 | 13′-9″ 4191 | 22 559 | 10 254 | 12 305 | 45 1143 | 17 5182 | 71 1803 | 64 1613 | 47 1194 |

| 47 x 18 1194 x 5486 | LLH-18 | 550-700 | 500- 640 | 4 1219 | 11,900 5,390 | 6 152 | 14′-6″ 4420 | 22 559 | 10 254 | 12 305 | 45 1143 | 19 5781 | 63 1600 | 71 1803 | 47 1194 |

| 51 x 20 1295 x 6096 | LLH-22 | 600-900 | 540-820 | 4, 5, 6 1219, 1524, 1829 | 15,300 6,930 | 6 152 | 16′-6″ 5029 | 24 610 | 12 305 | 12 305 | 47 1194 | 21 6401 | 77 1956 | 69 1753 | 51 1295 |

| 51 x 24 1295 x 7315 | LLH-22 | 600-900 | 540-820 | 6, 8, 10 1829, 2134, 2439 | 21,000 9,510 | 12 305 | 20’ 6096 | 30 762 | 8 203 | 12 305 | 53 1346 | 25 7620 | 77 1956 | 69 1753 | 51 1295 |

| 55 x 20 1397 x 5486 | LLH-22 | 650-900 | 590-820 | 5 1524 | 15,000 6,800 | 6 152 | 16′-6″ 5029 | 24 610 | 12 305 | 12 305 | 47 1194 | 21 6401 | 81 2057 | 73 1854 | 0 |

| 56 x 24 1422 x 7315 | LLH-26 | 650-950 | 590-860 | 5, 8 1524, 2134 | 26,000 11,780 | 18 457 | 18′ 5486 | 32 813 | 8 203 | 13 330 | 58 1473 | 25 7620 | 85 2159 | 75 1905 | 56 1422 |

| 56 x 26 1422 x 7925 | LLH-26 | 650-950 | 590-860 | 6, 8, 10 1829, 2134, 2439 | 28,500 12,910 | 18 457 | 20′-6″ 6248 | 32 813 | 8 203 | 13 330 | 57 1448 | 27 8230 | 85 2159 | 75 1905 | 51 1295 |

| 62 x 18 1575 x 5486 | LLH-22 | 700-1,100 | 640-1,000 | 4 1219 | 19,000 8,610 | 12 305 | 14′ 6807 | 24 610 | 10 254 | 12 305 | 47 1194 | 19 5791 | 91 2311 | 81 2057 | 62 1575 |

| 62 x 20 1575 x 6096 | LLH-22 | 700-1,100 | 640-1,000 | 4, 5, 6 1219, 1524, 1829 | 20,000 9,060 | 12 305 | 16′-0″ 4877 | 24 610 | 10 254 | 12 305 | 47 1194 | 21 6401 | 91 2311 | 81 2057 | 62 1575 |

| 62 x 24 1575 x 7315 | LLH-26 | 700-1,100 | 640-1,000 | 8, 10 2134, 2439 | 25,000 11,330 | 12 305 | 21′-0 6401″ | 36 914 | 5 114 | 13 330 | 62 1575 | 25 7620 | 91 2311 | 81 2057 | 62 1575 |

| 62 x 28 1575 x 8534 | LLH-32 | 700-1,100 | 640-1,000 | 8, 10 2134, 2439 | 43,500 19,710 | ** ** | 22′-2″ 6756 | 36 914 | ** ** | 14 356 | 65 1651 | 29 8839 | 92 2337 | 83 2108 | 62 1575 |

1 Grizzly section can be comprised of finger grizzlys, single deck, step deck, tapered caps or straight caps. Grizzly section can be solid plate to allow for full pan (contact factory for feeder specifics).

2 Weights can vary according to grizzly selection.

* Dimension denotes crusher mounting.

** Feeder is at a 5 degree decline. Consult factory for deck application.