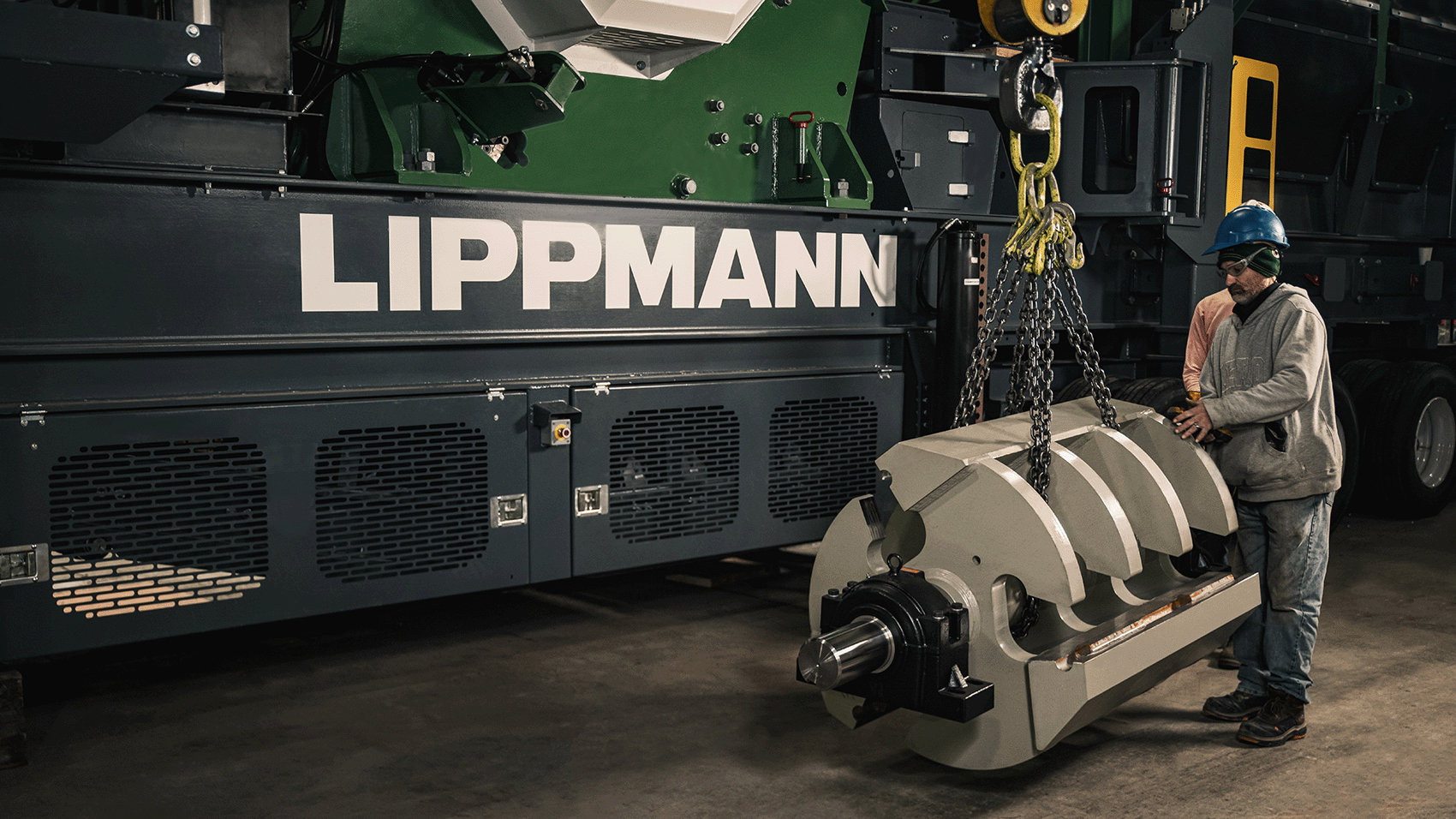

Rebuild with the Same Experts Who Built Your Machine

Only the OEM can guarantee that every bearing seat, rotor journal and shaft diameter returns to blueprint tolerance.

As part of our repair services, at Lippmann we have full capabilities for large scale heat treatment, sand-blasting, CNC machining and paint.

The end result is a factory-finish refurbishment that offers up to 60% savings compared to the cost of a new unit.

Why Rebuild Instead of Replace?

Save Capital

Stretch budgets by restoring large machines rather than buying new.

ONE Year Warranty

Typical rebuild turnaround is weeks, not months

Maintain OEM pedigree

Our technicians use the correct tools, drawings and specs originally used to build your equipment, ensuring dimensional stability and long-term reliability.

Key Advantages of an In-House Lippmann Rebuild

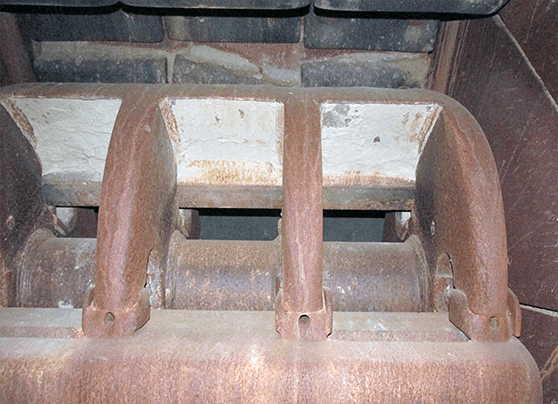

Comprehensive Disassembly & Inspection

Full teardown with ultrasonic testing of the pitman assembly, shafts and bearings.

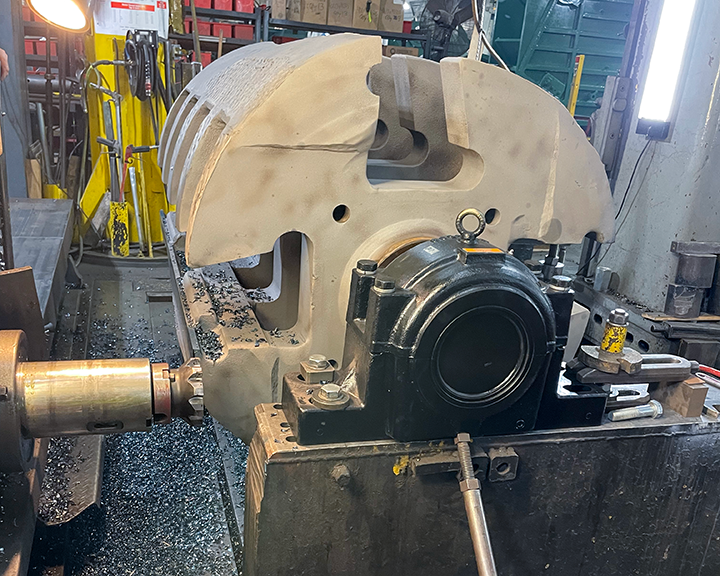

Precision Repairs & Re-Machining

Certified welders restore worn areas; critical fits are machined back to OEM tolerances for true alignment and stress relief.

Stress Relieving & Re-Chroming

Controlled heat-treatment plus optional hard-chrome diffusion improves wear resistance and dimensional stability through the stress relieving process.

Factory Finish

Sand-blasting, primer and OEM paint deliver a near-factory look while protecting against corrosion.

Our Five-Step Rebuild Process

Evaluation

Cost-benefit study versus new purchase; scope agreed.

Disassembly & Inspection

Complete teardown; NDT on shafts, rotors and the jaw crusher frame.

Rebuild & Replace

Welding, machining, heat treatment, and the installation of new components, as required (bearings, liners, gyratory cone heads).

Refinishing & Assembly

Stress relieving & re-chroming, paint, precision torque and clearance checks.

Final Test

Loaded and no-load run-in confirms that vibration, temperature, and power draw meet or exceed the original specifications for crusher maintenance peace of mind.

Ready for a Quote ?

Use the form below for a same-day crusher repair estimate.