Unmatched Mining Productivity

Since 1923, Lippmann has been designing and manufacturing premium crushing equipment. Today, Lippmann continues the legacy as your resource for complete systems solutions.

Whether your operation needs a complete primary crushing station or the flexibility of a wheeled or track-mounted crushing plant, Lippmann equipment is engineered to operate reliably in the toughest mining environments.

Backed by the best, our team is experienced in engineering, manufacturing, and supporting equipment for large aggregate quarries in remote locations, mining and international expansion mining.

HIGH PROFILE MINING PROJECTS

The Lippmann Edge

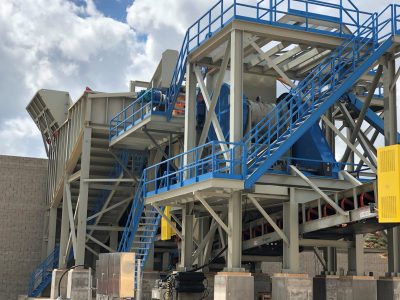

Primary Plant Process: Custom Design, Build, Install

The customer is our focus every step of the way, ensuring that specific site needs are addressed and the Lippmann equipment is custom fit for your application.

All Lippmann products are backed by unmatched customer service that respects your time and resolves any challenges as efficiently as possible.

- Identify Site Requirements

- Review & Approve Engineering Drawings

- Manufacturing Process

- Pre-Fit Assembly

- Paint & Final Finish

- Quality Testing

- Equipment Shipments Sent in Order of Assembly

- Field Installation with Certified Technician

Primary Stations

Lippmann’s range of large-model primary stations include 5062j, 4850j, 4248j, 3862j, and 3650j to suit your specific heavy-duty, high-volume crushing application. World-renown, truly massive jaws are unmatched in reliability, capacity and productivity, allowing you to achieve a higher tonnage.

YOU CAN RELY ON LIPPMANN FOR:

- Custom plant design

- Application-specific designs to ensure 100% customer satisfaction

- Meeting and exceeding your expectations for performance and production

- Equipment built for demanding production, strength, and a lifetime of dependability

- Rugged jaw construction with large shaft and components, and heavy frame

Wheeled Plant Crushing Systems

Lippmann covers your complete portable plant crushing system needs, from primary to tertiary crushing and all supporting auxiliary equipment to accomplish any site need.

WHEELED EQUIPMENT INCLUDES:

- Primary jaw plants 2950j – 4248j

- Primary impactor plants 4248i – 5860i

- Secondary and tertiary cone and impactor plants

- Screen plants 6’x20′ – 8’x20′ / 1.83m x6.10m – 244m x 6.10m

- Stackers

- Surge bins

- Splitter box