INDUSTRY: Aggregate, Recycle

material type: Rock, Concrete & Asphalt

Wheeled Impactor Plant

5860ip-w

Proven to be a durable, high performance and cost effective solution in a variety of applications. This Impact Crusher is designed specifically for demanding aggregate and recycle operations. Fabricated to provide cost efficient crushing solutions to customers, without losing strength or efficiency. Due to the varying crusher sizes, Lippmann is able to provide a solution to any crushing scenario no matter the size.

Standard Features & Options

Standard Features

- Andreas type impact crusher design

- Inspection door on side of the machine

- High ratio of reduction

- Hammers have four crushing positions to maintain a more consistent gradation and greater top size control

- No weld build-up required

- One gravity and one spring-loaded curtain with optional third grinding curtain

Options

- Hydraulic leveling jacks – (6) 70,000 lbs

- Six (6) run-on jack legs

- NEMA 12-motor control center

Technical Specs

| SPECIFICATIONS | |||

| RPM | 357-458 rpm | ||

| Feeed Size | 42″ | ||

| Feeder | 58″ x 20′ | ||

| Feeder Operating Speed | 830 rpm | ||

| Grizzly Length | 4′ | ||

| TRANSPORTATION | |||

| Tires | 315/80R22.5 | ||

| Hopper Module | 51,500 lbs | ||

| Quad | 78,250 lbs | ||

| King | 53,250 lbs | ||

| Total | 183,000 lbs | ||

| HORSEPOWER | |||

| Impactor | 400-500hp | ||

| Feeder | 50hp | ||

| CAPACITIES | |||||

| Minimum Setting | Capacity (tons) | Maximum Feed Size (inches) | |||

| Limestone | Gravel | Concrete | Asphalt | ||

| 2.5″ | 250-330 | 30″ | 12″ | 38″ | 38″ |

| 3″ | 260-340 | 30″ | 12″ | 38″ | 38″ |

| 4″ | 300-380 | 37″ | 16″ | 40″ | 42″ |

| 5″ | 380-450 | 37″ | 16″ | 40″ | 42″ |

| 6″ | 500-600 | 37″ | 16″ | 40″ | 42″ |

Lippmann reserves the right to make changes to the information and design of the machines on this website without reservation and notification to the users. Information at time of publication is considered accurate – Lippmann assumes no liability resulting from errors or omissions in this document.

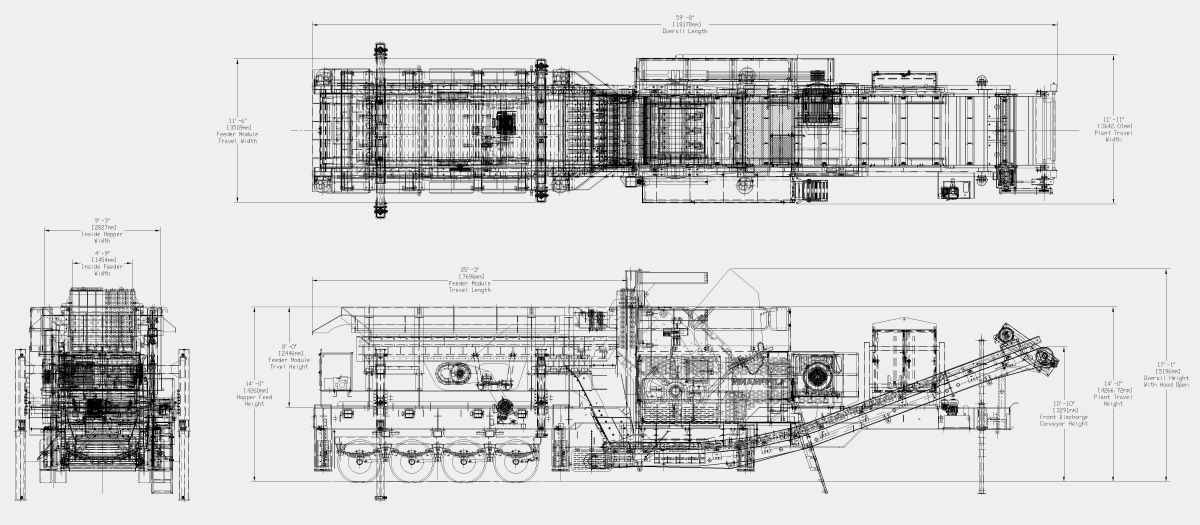

Diagrams