INDUSTRY: Aggregates, Mining, Recycling

Primary Crusher

4248j

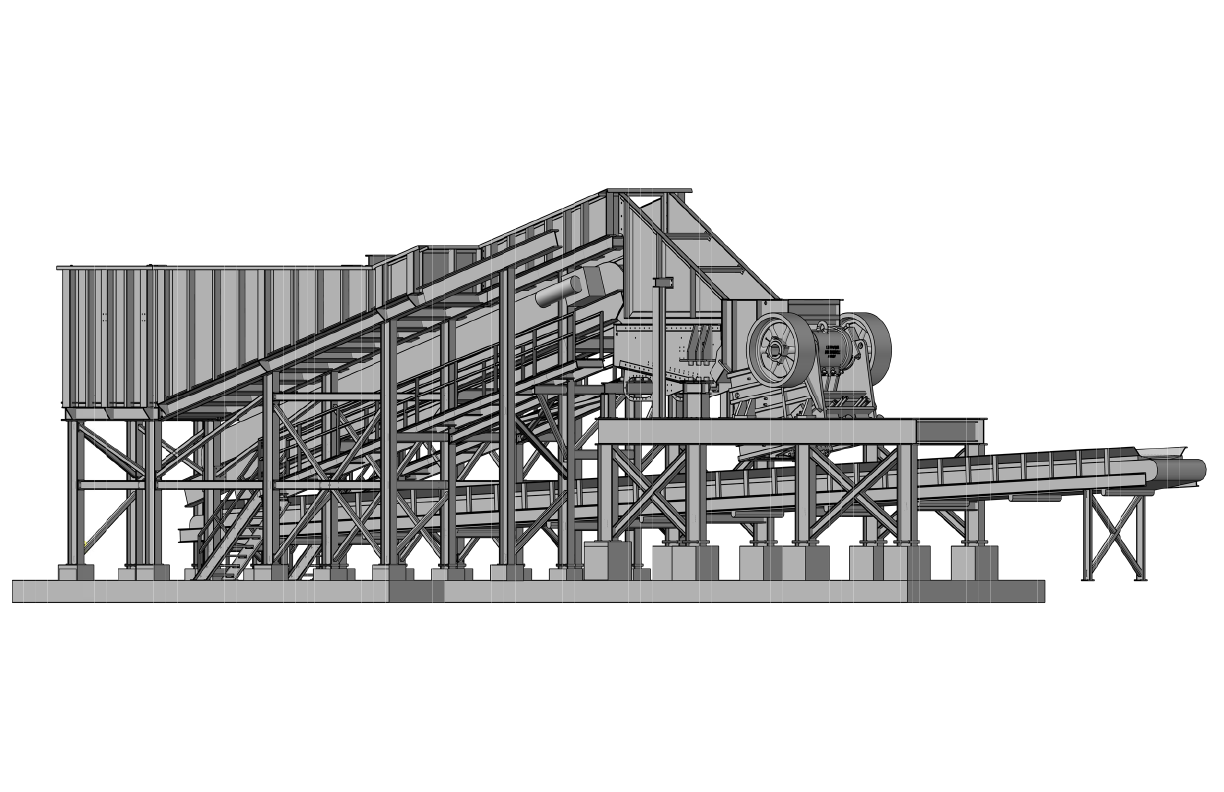

This jaw plant is designed for in-pit crushing, high capacity applications and provides unmatched production and reliability in the market.

It features an optional rock hammer and hopper extensions capable of handling large front end loaders or trucks and is specifically designed to handle 1000+ tons per hour making sure there is enough capacity in the hopper and conveyor to be able to obtain this.

Highlights

One piece steel pitman

Two heavy-duty flywheels, one grooved for V-belts

Application-specific structural design.

Massive rock box with optional extensions handles large front-end loaders.

Optional rock hammer helps keep material moving.

Operator control office positioned to keep a close eye on productivity.

Standard Features & Options

Standard Features

- Custom plant design

- Application specific designs to ensure 100% customer satisfaction

- Meets and exceeds expectations for performance and production

- Built for demanding production, strength, and a lifetime of dependability

Options

- Rock hammer

- Hopper extensions

Technical Specs

| Gape Size x Width | Horsepower | Capacity (inches) | Capacity (stph) | Weight |

| 42×48 | 250 | Minimum: 6 Maximum: 14 | Minimum: 386 Maximum: 1309 | 130,000 lbs |

| Toggle Plate Opening (inches) | Toggle Plate Opening (mm) | Capacity Range (Hydraulic Toggle) | Capacity Range (Manual Toggle) |

| 3 | 77 | 386-489 | 350-444 |

| 3.5 | 89 | 417-510 | 379-466 |

| 4 | 102 | 451-550 | 400-499 |

| 4.5 | 115 | 485-589 | 430-531 |

| 5 | 127 | 519-627 | 460-567 |

| 6 | 153 | 599-689 | 543-625 |

| 7 | 178 | 688-780 | 624-708 |

| 8 | 204 | 778-896 | 715-876 |

Lippmann reserves the right to make changes to the information and design of the machines on this website without reservation and notification to the users. Information at time of publication is considered accurate – Lippmann assumes no liability resulting from errors or omissions in this document.

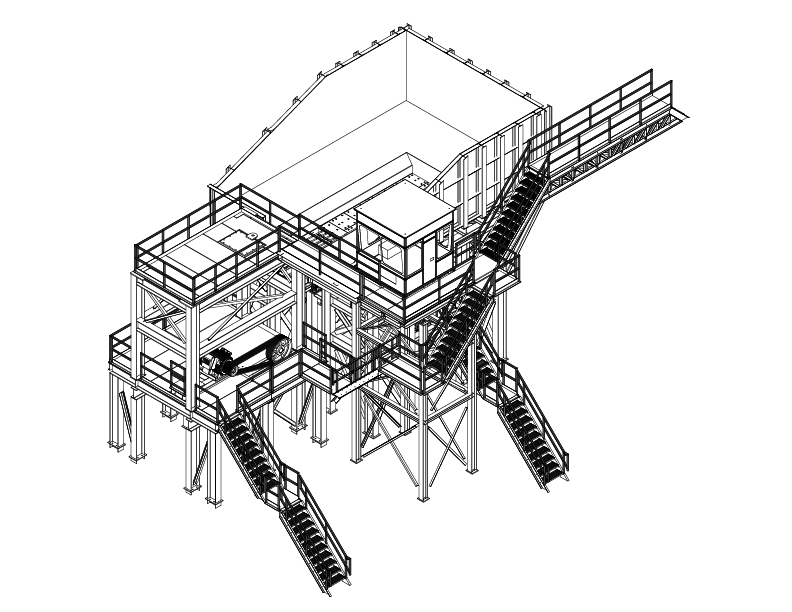

Diagrams