INDUSTRY: Aggregates, Mining, Recycling

Bare Impact Crusher

Bare Impactor

Proven in a variety of applications and materials, Lippmann impact crushers stand up to the most demanding aggregate, mining and recycling operations. Crush a wide range of materials like limestone, dolomite, gravel, basalt, copper reverts, concrete, and asphalt without losing strength or efficiency.

Whether portable, stationary, or skid-mounted, these rugged impact crushers provide consistently high production at an incredible value. For optimal throughput, impact crushers are equipped with Lippmann grizzly feeders and engineered for your most critical crushing scenarios.

Standard Features & Options

Standard Features

- Andreas-type impact crusher design

- Produces highly cubical product

- High ratio of reduction

- Hammers have four crushing positions to maintain a more constant gradation and greater top-size control

- No weld buildup required on wear surfaces

- Less capital outlay than competitive crushers

- High degree of product size control

- Wear components have long life due to advanced metallurgy

- Maintenance through inspection doors or by hydraulically opened hood (electric/hydraulic power unit is standard)

- Ideal for portable mounting

Options

- One gravity and one spring loaded curtain with optional third curtain allow easy adjustment from exterior of crusher

- 3 or 4 bar option

Technical Specs

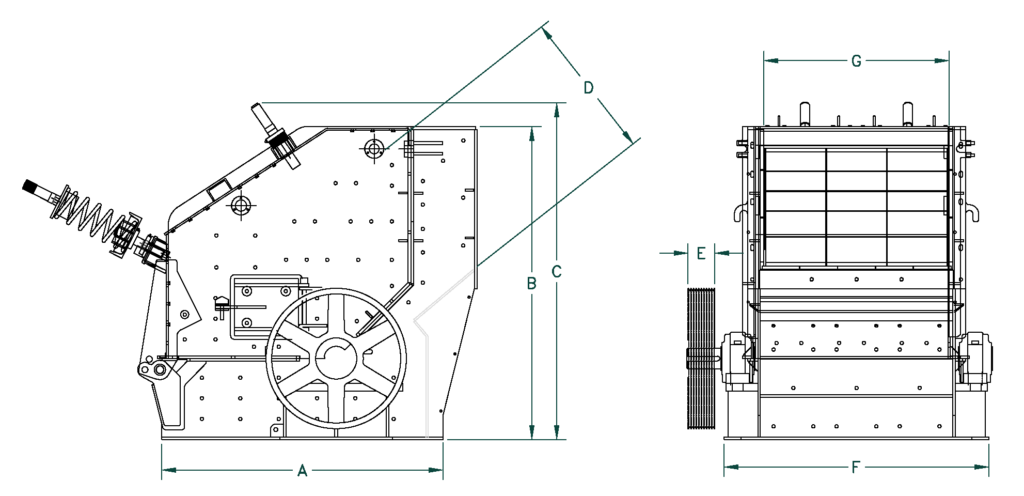

*See diagram below for letter reference.

| A | B | C | D* | E | F | G* | Weight (lbs./ Kg) | |

| 4248ip | 75″ 1911mm | 84″ 2134mm | 90″ 2286mm | 35″ 876mm | 7″ 143mm | 71″ 1797mm | 50″ 1257mm | 24,000 10,866 |

| 5165is | 79″ 2000mm | 91″ 2311mm | 99″ 2515mm | 31″ 775mm | 7″ 180mm | 89″ 2261mm | 67″ 1689mm | 35,800 16,239 |

| 5165ix | 88″ 2229mm | 96″ 2438mm | 104″ 2642mm | 40″ 1003mm | 12″ 295mm | 91″ 2299mm | 67″ 1689mm | 47,000 21,319 |

| 5165ip | 88 2229mm | 96″ 2438mm | 104″ 2642mm | 40″ 1003mm | 12″ 295mm | 91″ 2299mm | 67″ 1689mm | 49,000 22,226 |

| 5860ip | 106″ 2680mm | 111″ 2819mm | 112″ 2845mm | 48″ 1207mm | 9″ 238mm | 89″ 2248mm | 62″ 1562mm | 63,000 28,576 |

| GAPE X WIDTH (INCHES/MM) | HP (Electric Drive Motor) | CAPACITY (STPH/MTPH) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| MAXIMUM FEED SIZE (INCHES/MM) | HYDRAULIC TOGGLE OR MANUAL TOGGLE PLATE OPTION | MANUAL TOGGLE PLATE OPTION ONLY | |||||||

| Inches mm | LIMESTONE | GRAVEL | ASPHALT | CONCRETE | |||||

| 4248ip | 200 | 170-260 155-236 | STPH MTPH | 23 584 | 12 305 | 28 711 | 28 711 | 2 44 | 3 or 4 |

| 5165is | 200 | 230-365 210-331 | STPH MTPH | 31 787 | 16 406 | 34 864 | 34 864 | 2 38 | 4 |

| 5165ix | 220 | 225-425 204-385 | STPH MTPH | 31 787 | 16 406 | 34 864 | 34 864 | 2 51 | 4 |

| 5165ip | 300-500 | 250-450 227-408 | STPH MTPH | 31 787 | 16 406 | 34 864 | 64 864 | 2 51 | 4 |

| 5860ip | 400-450 | 400-1000 363-907 | STPH MTPH | 40 1016 | 18 457 | 42 1067 | 40 1016 | 3 64 | 4 |

Lippmann reserves the right to make changes to the information and design of the machines on this website without reservation and notification to the users. Information at time of publication is considered accurate – Lippmann assumes no liability resulting from errors or omissions in this document.