Trust our aggregate experience

The complete Lippmann crushing systems product line provides more solutions for your needs in demanding applications. Our team is experienced in engineering, manufacturing, and supporting equipment for every aggregate material processing application for primary and secondary stage crushing.

All Lippmann products are backed by unmatched customer service that respects your time and resolves any challenges as efficiently as possible.

The Lippmann Edge

Site Spread Development & Equipment Selection

The customer is our focus every step of the way, ensuring that specific site needs are addressed and the right Lippmann equipment is identified to fulfill your project requirements. Our aggregate experts have a wealth of knowledge to support your experience from start to finish. Whether you require individual jaw or impact crushers, custom transportable crushing plants, or complete 2- or 3-stage crushing systems, Lippmann will design the optimal solution for your specific aggregate operation.

- Identify Site Requirements

- Crushing, Plant & Custom System Selection

- Manufacturing Process

- Paint & Final Finish

- Quality Testing

- Equipment Delivery

- Field Installation with Certified Technician

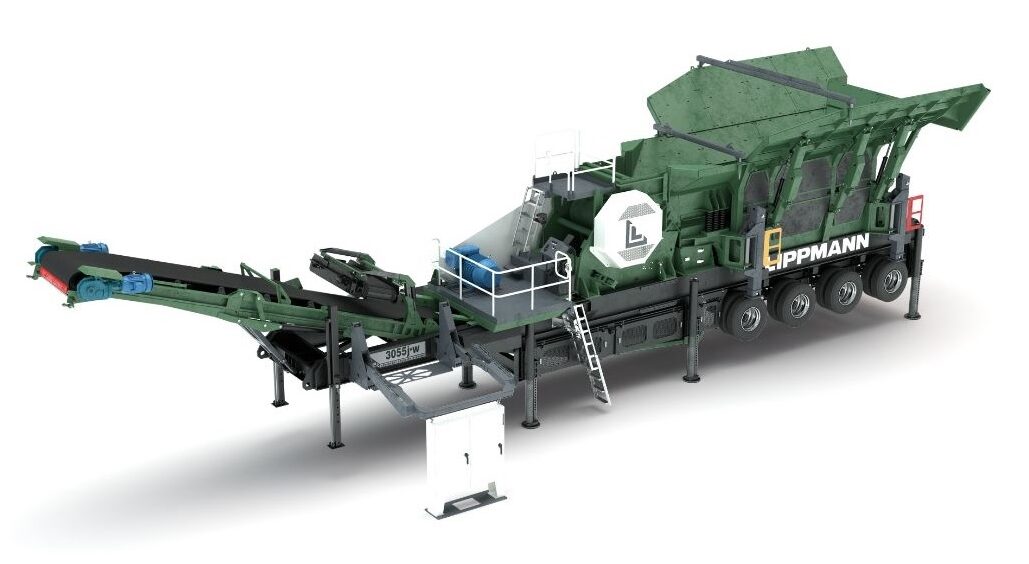

Wheeled Plant Crushing Systems

Lippmann covers your complete portable plant crushing system needs, from primary to tertiary crushing and all supporting auxiliary equipment to accomplish any site need.

Lippmann’s wheel-mounted crushing plants provide a durable, high-production crusher on a stout, easy-to-move truck frame. These plants also feature the rugged Lippmann feeder, capable of handling side or rear loading from various types of equipment.

Lippmann also offers multiple discharge conveyor configurations, including a front discharge configuration, an extended front discharge configuration, and a side discharge configuration. Combining standard configurations for various applications with a willingness to develop custom solutions for every plant gives each customer the kind of flexibility that translates into success in the field.

LIPPMANN WHEELED EQUIPMENT BENEFITS

- Custom plant design

- Application-specific designs to ensure 100% customer satisfaction

- Meeting and exceeding your expectations for performance and production

- Equipment built for demanding production, strength, and a lifetime of dependability

- Rugged jaw construction with large shaft and components, and heavy frame

Tracked Plant Crushing Systems

Lippmann has taken its philosophy of building the toughest mobile wheel-mounted jaw crushers on the market and applied it to its newest offering, the track-mounted jaw crusher. Known throughout the industry for its unmatched production and reliability, the track-mounted jaw crusher features a stout, torsional resistance chassis design with oversized tracks and a rugged impactor. This cost-effective plant provides the ease of movement expected from a tracked machine to maneuver around aggregate and recycle operations.